🏠 Why Spray Foam Is Replacing Fiberglass Insulation

- Matthew Lempe

- May 21, 2025

- 2 min read

Updated: Dec 1, 2025

For decades, fiberglass was the go-to insulation in homes and buildings across America. But today, that’s changing — fast. At Project Spray Foam LLC, we’re seeing more builders and homeowners making the switch to spray foam insulation for one simple reason: it outperforms fiberglass in every way that matters.

Here’s a closer look at why fiberglass is falling behind — and why spray foam is leading the future of energy-efficient, healthy buildings.

✅ 1.

Performance: Spray Foam Is in a League of Its Own

Fiberglass works by trapping air, but it’s vulnerable to air leakage, moisture, and compression over time. Spray foam insulation, on the other hand, forms a continuous, air-tight seal that:

Blocks air infiltration (up to 24x better than fiberglass)

Prevents moisture buildup and mold

Delivers higher R-values (insulating power) per inch

Doesn’t sag, shift, or deteriorate like fiberglass

This is critical in Florida’s hot, humid climate where energy efficiency and moisture control are everything.

🇺🇸 2.

Made in America vs. Imported Fiberglass

Many fiberglass products today are manufactured in China, raising questions about:

Quality control

Chemical content

Environmental standards

In contrast, high-quality spray foams like the ones we use at Project Spray Foam are made right here in the USA. They meet strict manufacturing standards and are designed for American homes and conditions — including extreme heat, humidity, and hurricane resilience.

☣️ 3.

Health: What You Should Know About Fiberglass Dust

Fiberglass may be marketed as safe, but installing or disturbing it releases fine glass particles and airborne dust that can:

Irritate eyes, nose, and throat

Trigger respiratory issues and asthma

Cause skin rashes

Pose risks with long-term exposure (especially in poorly ventilated areas)

This is particularly concerning during remodels or in attics and crawlspaces where fiberglass is exposed.

Spray foam, once cured, forms a sealed, non-toxic barrier that doesn’t shed particles into your air. It’s cleaner, safer, and better for indoor air quality — especially for families, seniors, and allergy sufferers.

🏆 4.

Long-Term Value and Efficiency

While spray foam may have a higher upfront cost than fiberglass, it pays for itself in energy savings and longevity. It:

Lowers your utility bills by up to 50%

Reduces HVAC strain

Increases property value and buyer appeal

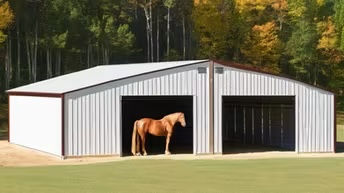

It’s also more effective in insulating hard-to-reach areas like rim joists, cathedral ceilings, pole barns, and metal buildings.

Fiberglass Had Its Time — Now Foam Leads the Way

At Project Spray Foam LLC, we believe your insulation should work smarter, last longer, and protect your home and health. That’s why more homeowners, contractors, and builders are making the switch to spray foam.

Ready to upgrade your insulation?

📞 Call us at [407-308-2257] or email Matt@projectsprayfoam.com for a free quote.

Let’s foam it right — the first time.

Comments